- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

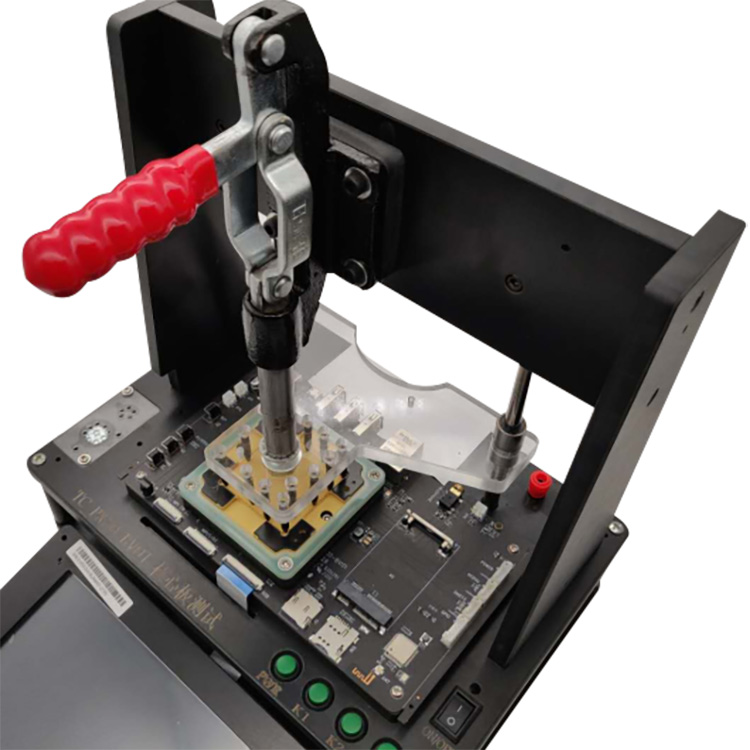

RV1126 Serial Debugging Board

RV1126 Serial Debugging Board made in China can be bought with Low Price from Thinkcore Technology. If you want Pricelist and Quotation, you can ask us by leaving a message.

Send Inquiry

Product Description

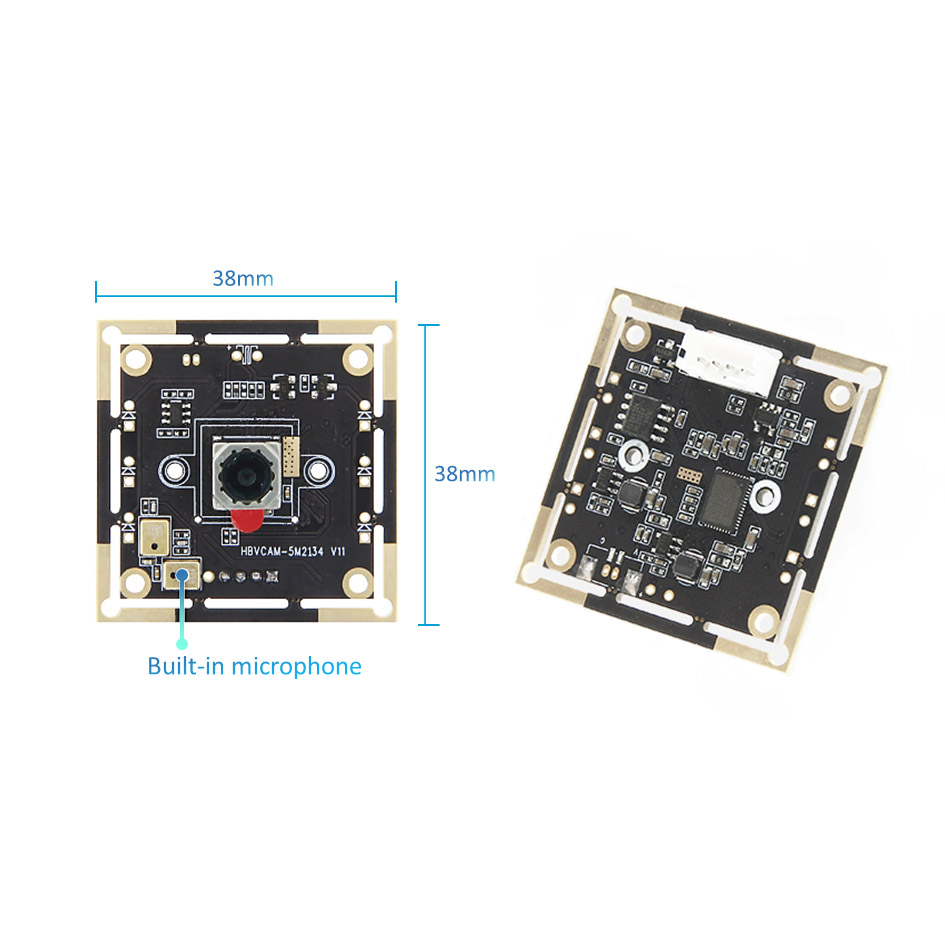

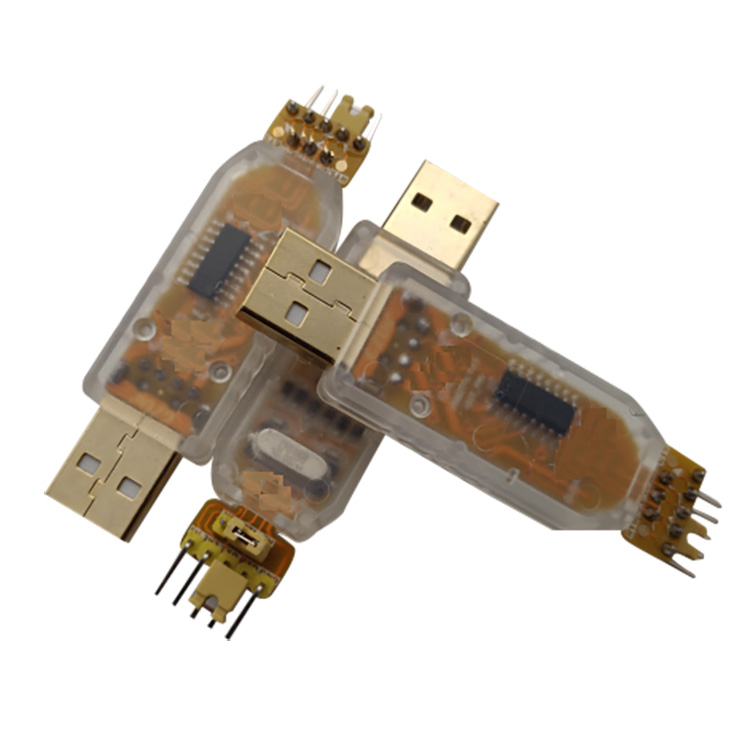

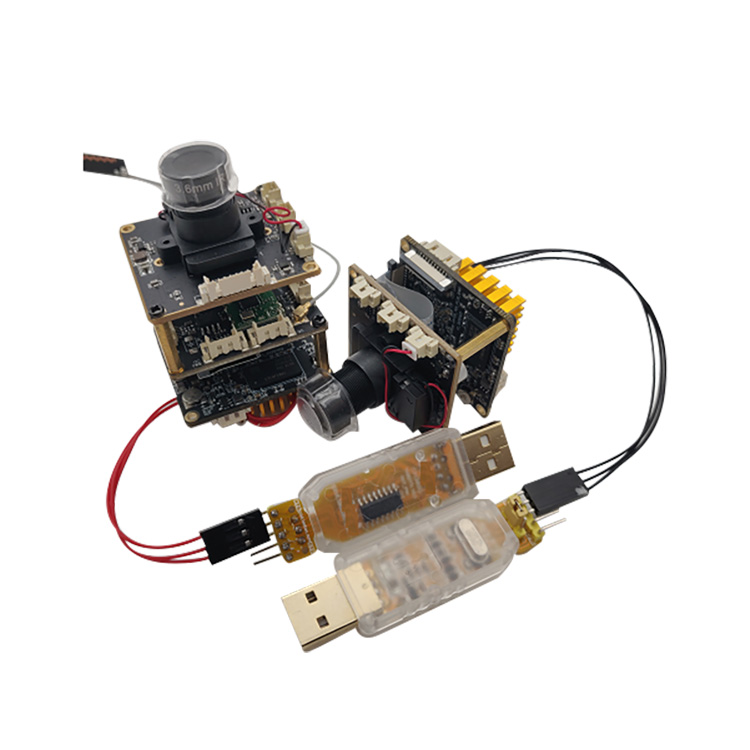

RV1126 Serial Debugging Board

7.FAQ

1. Do you have support? What kind of technical support is there?

Thinkcore reply: We provide the source code, schematic diagram, and technical manual for the core board development board.

Yes, technical support, you can ask questions via email or forums.

The scope of technical support

1. Understand what software and hardware resources are provided on the development board

2. How to run the provided test programs and examples to make the development board run normally

3. How to download and program the update system

4. Determine whether there is a fault. The following issues are not within the scope of technical support, only technical discussions are provided

⑴. How to understand and modify the source code, self-disassembly and imitation of circuit boards

⑵. How to compile and transplant the operating system

⑶. Problems encountered by users in self-development, that is, user customization problems

Note: We define "customization" as follows: In order to realize their own needs, users design, make or modify any program codes and equipment by themselves.

2. Can you accept orders?

Thinkcore replied:

Services we provide: 1. System customization; 2. System tailoring; 3. Drive development; 4. Firmware upgrade; 5. Hardware schematic design; 6. PCB Layout; 7. System upgrade; 8. Development environment construction; 9. Application debugging method; 10. Test method. 11. More customized services┉

3. What details should be paid attention to when using the android core board?

Any product, after a period of use, will have some small problems of this kind or that. Of course, the android core board is no exception, but if you maintain and use it properly, pay attention to the details, and many problems can be solved. Usually pay attention to a little detail, you can bring yourself a lot of convenience! I believe you will definitely be willing to try. .

First of all, when using the android core board, you need to pay attention to the voltage range that each interface can accept. At the same time, ensure the matching of the connector and the positive and negative directions.

Secondly, the placement and transportation of the android core board is also very important. It needs to be placed in a dry, low-humidity environment. At the same time, it is necessary to pay attention to anti-static measures. In this way, the android core board will not be damaged. This can avoid the corrosion of the android core board due to high humidity.

Third, the internal parts of the android core board are relatively fragile, and heavy beating or pressure can cause damage to the internal components of the android core board or PCB bending. and so. Try not to let the android core board be hit by hard objects during use

4. How many types of packages are generally available for ARM embedded core boards?

The ARM embedded core board is an electronic motherboard that packs and encapsulates the core functions of a PC or tablet. Most ARM embedded core boards integrate CPU, storage devices and pins, which are connected to the supporting backplane through pins to realize a system chip in a certain field. People often call such a system a single-chip microcomputer, but it should be more accurately referred to as an embedded development platform.

Because the core board integrates the common functions of the core, it has the versatility that a core board can customize a variety of different backplanes, which greatly improves the development efficiency of the motherboard. Because the ARM embedded core board is separated as an independent module, it also reduces the difficulty of development, increases the reliability, stability and maintainability of the system, accelerates time to market, professional technical services, and optimizes product costs. Loss of flexibility.

The three main characteristics of the ARM core board are: low power consumption and strong functions, 16-bit/32-bit/64-bit dual instruction set and numerous partners. Small size, low power consumption, low cost, high performance; support Thumb (16-bit)/ARM (32-bit) dual instruction set, compatible with 8-bit/16-bit devices; a large number of registers are used, and the instruction execution speed is faster ; Most data operations are completed in registers; the addressing mode is flexible and simple, and the execution efficiency is high; the instruction length is fixed.

Si Nuclear Technology's AMR series embedded core board products make good use of these advantages of the ARM platform. Components CPU CPU is the most important part of the core board, which is composed of arithmetic unit and controller. If the RK3399 core board compares a computer to a person, then the CPU is his heart, and its important role can be seen from this. No matter what kind of CPU, its internal structure can be summarized into three parts: control unit, logic unit and storage unit.

These three parts coordinate with each other to analyze, judge, calculate and control the coordinated work of various parts of the computer.

Memory Memory is a component used to store programs and data. For a computer, only with memory can it have a memory function to ensure normal operation. There are many types of storage, which can be divided into main storage and auxiliary storage according to their use. Main storage is also called internal storage (referred to as memory), and auxiliary storage is also called external storage (referred to as external storage). External storage is usually magnetic media or optical disks, such as hard disks, floppy disks, tapes, CDs, etc., which can store information for a long time and do not rely on electricity to store information, but driven by mechanical components, the speed is much slower than that of the CPU.

Memory refers to the storage component on the motherboard. It is the component that the CPU directly communicates with and uses it to store data. It stores the data and programs currently in use (that is, in execution). Its physical essence is one or more groups. An integrated circuit with data input and output and data storage functions. The memory is only used to temporarily store programs and data. Once the power is turned off or there is a power failure, the programs and data in it will be lost.

There are three options for the connection between the core board and the bottom board: board-to-board connector, gold finger, and stamp hole. If the board-to-board connector solution is adopted, the advantage is: easy plugging and unplugging. But there are the following shortcomings: 1. Poor seismic performance. The board-to-board connector is easily loosened by vibration, which will limit the application of the core board in automotive products. In order to fix the core board, methods such as glue dispensing, screwing, soldering copper wire, installing plastic clips, and buckling the shielding cover can be used. However, each of them will expose many shortcomings during mass production, resulting in an increase in the defect rate.

2. Cannot be used for thin and light products. The distance between the core board and the bottom plate has also increased to at least 5mm, and such a core board cannot be used to develop thin and light products.

3. The plug-in operation is likely to cause internal damage to the PCBA. The area of the core board is very large. When we pull out the core board, we must first lift one side with force, and then pull out the other side. In this process, the deformation of the core board PCB is inevitable, which may lead to welding. Internal injuries such as point cracking. Cracked solder joints will not cause problems in the short term, but in long-term use, they may gradually become poorly contacted due to vibration, oxidation and other reasons, forming an open circuit and causing system failure.

4. The defective rate of patch mass production is high. Board-to-board connectors with hundreds of pins are very long, and small errors between the connector and the PCB will accumulate. In the reflow soldering stage during mass production, internal stress is generated between the PCB and the connector, and this internal stress sometimes pulls and deforms the PCB.

5. Difficulty in testing during mass production. Even if a board-to-board connector with a 0.8mm pitch is used, it is still impossible to directly contact the connector with a thimble, which brings difficulties to the design and manufacture of the test fixture. Although there are no insurmountable difficulties, all the difficulties will eventually be manifested as an increase in cost, and the wool must come from the sheep.

If the gold finger solution is adopted, the advantages are: 1. It is very convenient to plug and unplug. 2. The cost of gold finger technology is very low in mass production.

The disadvantages are: 1. Since the gold finger part needs to be electroplated gold, the price of the gold finger process is very expensive when the output is low. The production process of the cheap PCB factory is not good enough. There are many problems with the boards and the product quality cannot be guaranteed. 2. It cannot be used for thin and light products like board-to-board connectors. 3. The bottom board needs a high-quality notebook graphics card slot, which increases the cost of the product.

If the stamp hole scheme is adopted, the disadvantages are: 1. It is difficult to disassemble. 2. The core board area is too large, and there is a risk of deformation after reflow soldering, and manual soldering to the bottom board may be required. All the shortcomings of the first two schemes no longer exist.

5. Will you tell me the delivery time of the core board?

Thinkcore replied: Small batch sample orders, if there is stock, the payment will be shipped within three days. Large quantities of orders or customized orders can be shipped within 35 days under normal circumstances

Hot Tags: RV1126 Serial Debugging Board, Manufacturers, Suppliers, China, Buy, Wholesale, Factory, Made in China, Price, Quality, Newest, Cheap

Related Category

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

Related Products